Better, faster, smarter

Harnessing innovation to accelerate the

green energy systems of tomorrow

1 Offshore excellence

Ensuring excellence throughout the lifecycle of an offshore wind farm

From development to design and from construction to operation, the life cycle of an offshore wind farm presents countless opportunities to optimise, automate, and innovate. Across multiple innovation teams, we’re working to apply the latest technologies to every part of what we do as an offshore wind developer. Using everything from simple design principles to statistical modelling, drones, and AI, our innovation projects already save time and money, enabling faster and more confident business decisions, and pushing the boundaries of what it means to be an offshore wind developer.

Start exploring the cases →

1 Offshore excellence / Design cases

The loads exerted on offshore wind turbines depend on the way the turbines in a wind farm interact, as one turbine’s wake reduces the flow of air that reaches other turbines. This project implemented dynamic wake meandering representations into our own wind turbine simulations. This can save hundreds of tons of steel per wind farm by reducing conservatism in our loads and enabling lighter support structures. It is also paving the way for understanding much more intricate aspects of wind farm flow and turbine interaction.

Transporting parts and vessels for offshore wind installation is a complex operation that takes place in an even more complex and often unpredictable global supply chain market. Our industry-leading tool Optilog helps project teams evaluate potential logistics arrangements, reducing supply chain and installation risks that could affect up to 20 % of a project's total capital expenditure. The Optilog dispatch model can mitigate the risks of transportation by modelling logistics tasks, simulating everything from component transport tasks to stockpile forecasts and multi-vessel dependencies.

Monopile foundations are often designed based on conservative assumptions about their interactions with soil, leading to inefficient use of resources. To combat this and reduce monopile weights by up to 1 %, we’re incorporating methodologies and soil reaction data from the award-winning Pile-Soil Analysis Project into our machine learning models, including physics-informed neural networks. With these, we expect to accurately capture soil-pile interaction physics, creating a reliable surrogate that allows us to design monopiles more efficiently, cheaply, and with a reduced carbon footprint.

We’re constantly seeking to optimise the design of our most used wind turbine foundation: the monopile. The PICASO project provides Ørsted with industry-leading monopile design methods that are enabling leaner and more robust monopile foundations for our future windfarms with up to 20 % reduced penetration depth and substantially lower cost.

Together with the University of Oxford, we’re exploring the effects of cyclic loading on the monopile through laboratory tests, theoretical and computational works, and medium-scale field tests in clay and sand. This unprecedented data and sophisticated modelling enables us to better understand the physics of offshore wind’s foundations better than ever before.

How can we reduce the weight of North Sea monopiles by up to 5 %? Cone penetration testing (CPT) is used to assess the properties of soil to inform the design of wind turbine foundations and other offshore facilities. We recently concluded a three-year joint industry project to develop a robust set of guidelines for CPT in silty and transitional soils, which will reduce risks and conservatism of facility designs and installations. The project included in-situ testing, laboratory testing, calibration chamber and centrifuge testing, and numerical modelling.

Carbon Trust OWA: Cone Penetration Testing in Silty Soils (CSi). Partners: Ørsted (Lead Partner), Equinor, RWE, ScottishPower Renewables, Shell, Vattenfall.

Today’s power grids include fewer and fewer conventional thermal power plants with high natural inertia and more invertor-based generating assets with low natural inertia, like wind turbines. This means there’s a greater need for stability services such as inertia, which can also provide new revenue streams. Together with equipment manufacturers, we’re facilitating the deployment of an energy storage static synchronous compensator (ES-STATCOM). This offers up to a 20 % reduction in footprint and shows great potential for unlocking business upsides by removing the need for synchronous condensers and improving the utilisation of existing equipment.

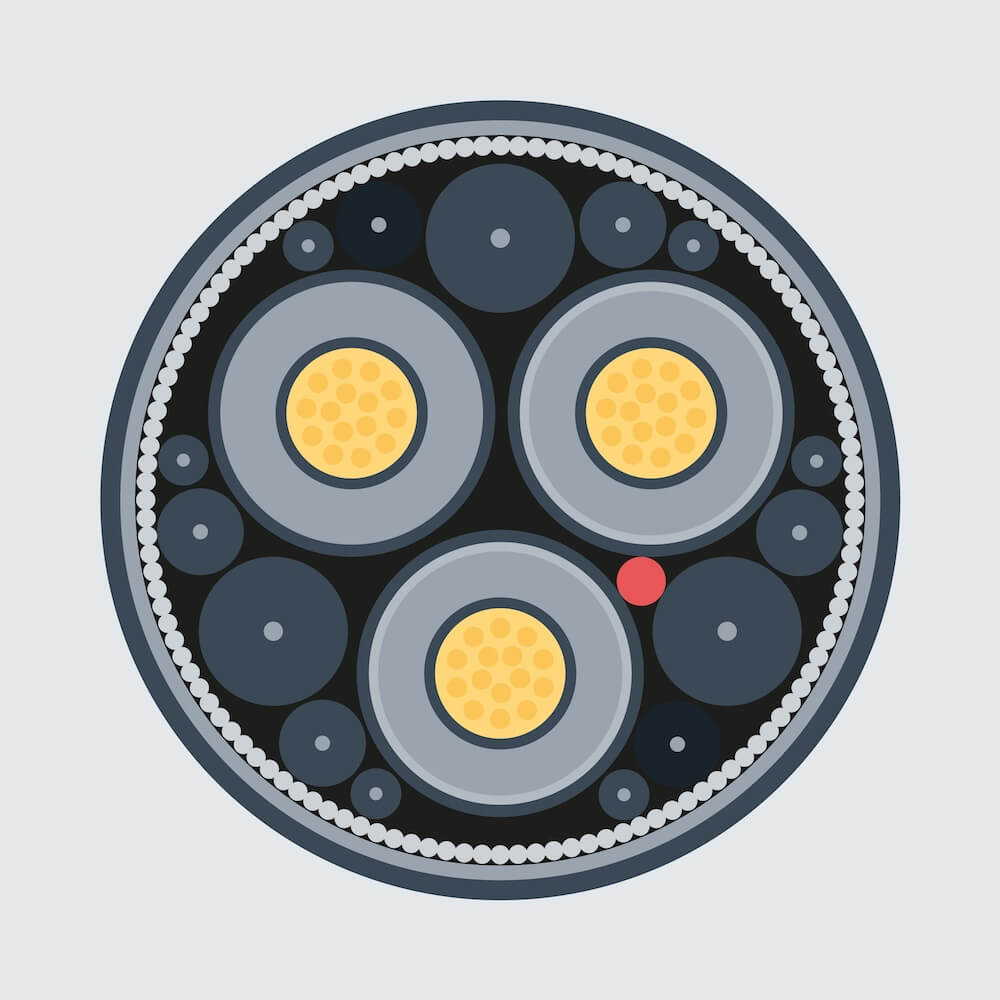

Cable installation takes place in a range of weather conditions that cables must be designed to withstand. OPERA is our AI-powered installation optimisation tool that defines weather operability limits by analysing key cable parameters. Predictions are powered by advanced machine learning models, drawing insights from thousands of simulations that replicate real-world installation scenarios. The tool allows us to evaluate cable designs within seconds instead of months or years, while also proactively identifying any risks.

The cables used to export power from an offshore wind farm are rated according to the peak temperatures they experience. Conventional ratings don’t consider how often these peak temperatures occur. Using risk-based cable design, which harnesses the power of stochastic modelling, fundamental physics, and thousands of simulations, we can better estimate the temperatures that cables experience in different operating environments and quantify the financial risk of curtailment. By optimising cable design, we’re able to boost power throughput by up to 8 %, while also mitigating operational issues and minimising up to 5% power loss during contingencies.

Offshore wind turbines and their foundations are exposed to some of the most extreme weather conditions on the planet. So what happens when a hurricane hits? What if turbines lose connection to the grid? Our hurricane and grid loss event simulator is a probabilistic tool that can quantify the risk related to these events and show how our design contingencies mitigate them. In its first application, we used the tool to demonstrate to the insurers of our projects off the east coast of the US how battery storage and autonomous operation capabilities would de-risk our projects against these extreme events. For example, for a 1 GW offshore wind project, it is estimated our simulator could save up to 15 thousand tonnes of steel and reduce CO2 emissions by approximately 30 thousand tonnes.

We’ve redesigned suspended internal platforms for our offshore wind turbine foundations by applying the design principles reduce, remove, and standardise. By using laser-cut, bent steel plates assembled with rivets, we’ve reduced the need for welding by 90 %. We’ve removed unnecessary and outdated components. And we’ve simplified climate barriers, railings, and hatches. Together, these innovations have reduced the total cost of ownership of suspended internal platforms by approximately 20 %, allowed us to expand our supplier base, and enabled local content to a larger extent.

1 Offshore excellence / Development cases

In the US, the Inflation Reduction Act is expected to unlock over USD 500 billion in tax credits by 2030, supporting sustainable financing for future clean energy projects. Through Ørsted Ventures, we’ve invested in Crux, a company that’s building a platform to foster efficient tax credit transfers through an online marketplace, collaboration tools, and post-transaction management. Together, we aim to drive favourable and sustainable finance to fund the growing clean energy market in the US.

Writing bids for new offshore wind farm tenders is an intricate process that demands considerable effort. We’ve started using generative AI to save hundreds of hours and optimise the bid process, from assessing the request for proposals and decoding tender documents to writing the bid. But our vision extends beyond that. We'll use AI to analyse the competition and equip our unique internal bid database with AI to craft bids with greater benefits for local communities, the environment, and investors.

How much underwater noise does an offshore wind turbine create during operation? We answered this question through the UnNo-X study, demonstrating that offshore wind is even safer for marine life than previously estimated. Providing noise estimates when we undertake environmental impact assessments is a critical part of the permitting process for an offshore wind farm. UnNo-X is an operational noise study that will mitigate risks and concerns about underwater noise when ensuring permits for future offshore wind farms. Normally, we use a simulated model to project expected noise levels. Our study set out to compare simulated noise levels to actual recorded noise generated by operating wind farms in Germany. It found that actual noise levels from 8 MW+ turbines were far lower than predicted by the models.

We’ve designed, built and patented the industry’s first Unmanned Metocean Survey Vessel, which uses lidar to accurately predict offshore wind generation at prospective sites. The vessel can remain at sea for a year, in waters up to 200 metres deep, in any sea state. It can be deployed faster, safer, and with better accessibility – all while gathering more data at up to 40 % less cost than conventional Light Detection and Ranging (LiDAR) buoys.

1 Offshore excellence / Operations cases

As Ørsted feeds more wind power into national electricity grids, we must report and rectify any issues that could impact the wider grid, and comply with obligations relating to the impact we have on the environment. We use condition monitoring models to predict issues from Supervisory Control And Data Acquisition (SCADA) and other sensor system data on our wind turbines and substations. This allows us to monitor as many of these issues as possible in a robust and consistent way, so that swift action can be taken to rectify them.

LiDAR equipment that measures windspeed on the nacelles of offshore wind turbines needs to be calibrated to make them accurate. We’re partnering on WindCal 2.0, a project to automate the calibration process to make it 3 times more accurate and 4 times faster than conventional calibration techniques. The project is funded by the Danish Energy Technology Development and Demonstration Program, led by DTU Wind & Energy Systems, and includes partners Siemens Gamesa and Vaisala. The new calibration technology is being demonstrated at Høvsøre test centre in Denmark.

As demand for electricity grows and distribution grids change, it’s crucial for energy companies like Ørsted to be able to forecast renewable generation and energy demand as accurately as possible. That’s why, through Ørsted Ventures, we’ve invested in Amperon. This US-based start-up provides next-generation analytics for the energy transition, significantly increasing forecasting accuracy, reducing costs, and enhancing revenue from energy trading. Amperon’s software offers renewable generation and demand forecasts, aiding companies like Ørsted in making better-informed decisions and navigating extreme weather events.

Inspecting offshore wind turbines is a labour-intensive and time-consuming task which involves technicians entering confined spaces. With Confispace, we can halve the number of technicians involved, improve safety and reduce inspection time by up to 80 % using inspection drones and AI analytics. Sensors on the drone quickly scan the confined space of the transition piece and monopile and send the data to the cloud where AI extracts insights from the inspections.

Wind turbine rotors are designed to capture the energy of the wind. These structures are built to be sturdy and reliable, capable of withstanding powerful forces. However, even minor irregularities in the rotors can cause imbalances, leading to premature wear and tear. With PowerPitch, we can prevent this and extend the lifetime of wind turbines, ensuring that they operate at optimal efficiency. By analysing historical data, PowerPitch can identify potential imbalances and provide new settings for the turbine controller to address them.

We’re committed to building renewable energy projects that have a positive impact on biodiversity – not least when it comes to birdlife. That’s why we’ve invested in Norwegian start-up Spoor, which uses AI to identify and track birds in and around wind farms. To date, Spoor’s technology has monitored over 65,000 hours of footage, and tracked over 625,000 birds. What we learn working with Spoor can help us refine wind farm project design in a way that we’re confident will minimise any risk of collision with birdlife.

Lifting cargo and tools from a vessel to the top of an offshore wind turbine used to be carried out entirely using cranes, taking up to 30 minutes every time. Today, we’re the first offshore wind company in the world to introduce heavy-lift drones to do some of this work. Drones make cargo transfer much faster and safer, minimising turbine downtime and time spent offshore, as well as reducing the environmental impact. In October 2023, we began trialling autonomous drones with a capacity of 68 kg at our Hornsea 1 offshore wind farm in the UK. We aim to reach a point where all cargo required for offshore operations can be moved with drones.

As our offshore wind portfolio grows, so does the number of components we use. This presents the opportunity to make significant time and money savings and improve sustainability by scaling the refurbishment of these components wherever possible, rather than simply replacing them. For minor steel components, refurbishment can reduce carbon dioxide emissions by up to 60 %, and in general we can save up to 30 % on costs. For major components, such as generators and gearboxes, lead time, cost, and steel consumption can be significantly reduced.

Our offshore wind turbine technicians need to transfer from vessels to turbines and vice versa in challenging sea conditions – and they need to do it safely. Developed in collaboration with Rutter Inc, Wave Signal is a vessel-mounted solution that uses the vessel’s radar to track incoming waves in real time. The system can detect waves up to two minutes away, giving time to plan crew transfer at the safest possible moment, increasing overall reliability and accuracy of transfer in difficult conditions. Wave Signal is currently being rolled out globally across all operational crew transfer vessels. Future developments include a traffic light system and other features to help the skipper and transferee make safe decisions.

2 Systems integration

Systems integration towards decarbonising the world economy

Systems integration holds the key to solving the major challenges of the global green energy transition: From balancing variable supply and demand to decarbonising those sectors that can’t be directly electrified, such as heavy industry, transport, and heat – all while enabling us to generate affordable, sustainable, and reliable energy. Systems integration means thinking about generation and production, transmission and distribution, storage and conversion, and offtake and consumption. And we’re already making great strides to achieve this.

Start exploring the cases →

2 Systems integration / Trading cases

The physical electricity markets run 24/7, 365 days a year. From our trading floor in Copenhagen, Ørsted monitors multiple markets simultaneously to maximise the value of our assets. But the number of products to trade and data to consider is so large that humans alone can’t do the job. That’s why we use automatic trading tools, which leverage machine learning to predict future power prices and generation from our portfolio and execute trades autonomously. We recently built our own system that currently performs tens of thousands of trades a day, outperforming external benchmarks. By leveraging these powerful tools, we can focus on finding opportunities in the markets and adding even more value.

We’re co-sponsoring a competition that aims to speed up the global transition to net zero by focusing on development of new and improved forecasting and energy trading solutions. The competition, which launched on 19 February 2024, was organised by the IEEE Power and Energy Society Working Group on Energy Forecasting and Analytics. It consists of two tracks – forecasting and trading – and participants are encouraged to enter in both, with a total available prize pot of USD 21,000.

2 Systems integration / Portfolio cases

How can we maximise value, maintain financial stability, and limit risks? These are the questions addressed by our Asset Portfolio Optimiser, developed by our Digital Innovation team and Strategic Portfolio Management. In development since summer 2023, our tool forecasts investment in future projects across various markets and technologies, from development to decommissioning. It utilises our proprietary forecasts for build-out potentials, costs, and power prices. Central to our portfolio and strategic reviews, it enables us to assess five times more projects than traditional methods, facilitating faster, informed decision-making.

2 Systems integration / Carbon Capture and Storage cases

In the battle against climate change, we can go further than reducing carbon emissions: We can actively remove carbon dioxide from the atmosphere through negative emissions. That’s the objective of our carbon capture and storage project, the Ørsted Kalundborg CO2 Hub, which has been awarded a 20-year contract by the Danish Energy Agency. From 2026, the project will capture 430,000 tonnes of biogenic CO2 annually from our wood chip-and straw-fired heat and power stations at Asnæs and Avedøre. The CO2 will then be shipped to Norway and stored in a reservoir in the North Sea.

Storing captured carbon dioxide onshore in Denmark promises to be a game changer in the Northern European carbon capture and storage (CSS) industry. Together with Equinor – offering strong, long-term expertise in CO2 storage – and Nordsøfonden, Ørsted has obtained permission from the Danish Energy Agency to explore the potential for CO2 storage near the Kalundborg area. It’s happening as part of the state's tender for exploration licenses for CO2 storage. Onshore storage can benefit from economies of scale and, compared with offshore storage options, it entails shorter transport distances and more cost-effective onshore storage development.

2 Systems integration / Power to X cases

A hybrid power plant (HPP) combines power generation, like wind or solar, with storage and conversion technologies, like batteries or electrolysers. This way, when generation is greater than demand, electricity can be stored to a battery or converted via Power-to-X – and vice versa when demand is greater than generation. This not only increases efficiency, but also asset profitability. We’re collaborating with the Technical University of Denmark to investigate how HPPs can operate with offshore wind farms. The project involves developing an HPP controller and analysing the stability, interoperability, and capabilities of different HPP technologies.

2 Systems integration / Storage cases

The ability to store energy is an essential part of a renewable-based energy system, where supply and demand need to be carefully balanced. Future Energy Storage Studio is a collaboration between Ørsted and industry partners, including Newlab, to advance early-stage long-duration, and alternative energy storage technologies. Through the project, we’re supporting start-ups like Electrified Thermal Solutions, VRB Energy, EarthEn and PolyJoule on their path to commercialisation – and in turn gaining new insights and capabilities from their work.

To reach net-zero by 2050, the UK needs to step up a gear to expand its offshore wind capacity, with energy storage being vital to success. In particular, the UK will need approximately 100GWh of energy storage, with Long Duration Energy Storage (LDES) being a significant contributor. A recent government study into the benefits of LDES stated that 12GW by 2035 would likely reduce emissions intensity by 10-28 %, and liquid air energy storage (LAES) alone could offer consumer savings of up to GBP 3 billion by 2050.

In 2023, alongside energy storage innovator Highview Power, we initiated an in-depth analysis into the role of LAES co-located with offshore wind. Preliminary results show that LAES has the potential to support energy balancing of offshore wind as well as offering much needed services to support stability of and access to the grid where the wind farm is connected.

In Pinal County, AZ, the Eleven Mile Solar Center is a 300-MW solar farm spanning 2,000 acres, with a 300-MW, four-hour battery energy storage system. Once online this year, it’ll be one of the largest battery energy storage systems built in a single phase in the US. The project will generate more than 900,000 MWh of energy annually – enough to power nearly 64,000 homes. Two hundred megawatts of the project’s energy production will power Meta's Mesa Data Center through an agreement with the local utility Salt River Project (SRP). Additional energy will be available to SRP’s customer base.

2 Systems integration / End use cases

What if data centres were located alongside offshore wind farms, allowing for scale, access to seawater for cooling, and synergies with offshore wind infrastructure and processes? We’re looking into it. Power consumption by data centres is expected to triple in the next three years. To meet this growing demand sustainably will require round-the-clock access to renewable energy sources. The colocation of data centres and offshore wind, with all the challenges it entails, might hold the key to future net-zero data centres at scale.

3 Partnering for impact

Partnerships & collaboration to scale impact

We live in an era of unprecedented technological progress – but one overshadowed by the climate crisis. The challenge for a renewable energy leader like Ørsted is to find the technologies that will help solve that crisis. But we can’t do it alone. On top of our in-house innovation capabilities, we’re working to unite industry peers, investors, start-ups, research organisations, universities, and others at the cutting edge of renewable energy innovation. We want to be a catalyst, to bring this innovation to fruition, where it can have a real, positive impact on people and the planet.

Start exploring the cases →

3 Partnering for impact / Cases

“Democratise AI” is an initiative that empowers Ørsted employees with intelligent tools that can enhance their technological capabilities, increase efficiency, and foster a culture of innovation to solidify our leadership in green energy. Across our organisation, we’ve built a community of about one thousand colleagues who are interested in AI and exploring the value it can bring to their work.

Our new start-up accelerator programme, Ørsted Propel, kicked off its first round in partnership with Rockstart and a focus on systems integration. We received over 150 applications and selected eight finalists to sign with four start-ups. Our new partners have the chance to accelerate their solutions by validating their commercial potential, while we gain insight into an array of new technologies.

Our innovation hubs exist to foster local green energy innovation by collaborating with universities, research organisations, start-ups, and investors. In turn, the hubs provide these organisations with a front door for collaborating with a global green energy leader. In 2023, we engaged with over 150 organisations and launched a UK and Ireland innovation hub, adding to our existing hubs in the US.

Sustainable recycling is core to developing our circular decommissioning practices. And in Northern Ireland, local waste specialist Plaswire is the perfect partner for our onshore wind farms. Our successful pilot project, involving the shredding of blades for reuse in construction materials, found a cost-efficient method to recycle 100 % of onshore wind turbine blades. Our continuing partnership aims to scale the technology for use in large-scale decommissioning projects.

We’re dedicated to working with academic institutions, where we sponsor research activities, offer industrial PhD scholarships, and participate in joint industry projects. In 2023, we partnered with 52 universities and research institutes, conducting 61 ongoing R&D projects worldwide. We continue to work with world-class institutions, including the University of Oxford, Massachusetts Institute of Technology, and the Technical University of Denmark.

We’re proud to continue working with the Carbon Trust on the Offshore Wind Accelerator (OWA) Programme that we helped found more than 15 years ago. Today, the programme is the world’s leading forum for collaborative innovation between all the major offshore wind developers, delivering almost 200 projects to date. It drives financial, social, and environmental sustainability across the sector. The GBP 100 million investment in OWA over its first 10 years is projected to yield GBP 34 billion in sectoral savings in Europe by 2030.

Innovation at Ørsted

How we’re harnessing innovation to create the green energy systems of tomorrow

At Ørsted, we believe that innovation is critical to reaching our vision of a world that runs entirely on green energy. Advances in technology have already brought down the costs of renewable energy, making it cost competitive with fossil fuels — and we believe we can continue to harness existing and new technologies to make green energy more affordable, reliable, efficient, and sustainable across the value chain.

Innovation is core to our business. As the world’s largest developer of offshore wind energy, Ørsted led the industry in scaling up offshore wind technology and driving down its costs. Today, our offshore wind assets comprise more than 1,900 spinning turbines powering millions of homes across three continents, as well as our industry-leading patent and IP portfolio, our reservoir of technical know-how, and our pipeline of technologies to enable the next generation of offshore wind.

We know what it takes to scale an emerging technology from early adoption to mass deployment. And we’re now applying those lessons to scale technologies across green fuel production, energy storage, and carbon capture. Just as we’re investing in technical improvements in the design, construction, and operation of our offshore fleet, we're constantly exploring ways to reduce costs and boost power generation from our onshore wind and solar assets.

Our R&D is driven internally by talented colleagues with deep science and engineering expertise. These efforts continually sharpen Ørsted’s competitive edge and enable us to thrive in an evolving industry. We also collaborate with innovators in green technology to transform advanced capabilities into real-world impact in major infrastructure projects by investing in cutting-edge start-ups, serving as an early customer of emerging technologies, leading joint industry projects, collaborating with prominent universities around the world, and more.

Some projects together with partners to highlight include:

- We commercialised renewable energy research and technology, transitioning from the lab to the field through our ongoing academic partnerships with more than 50 leading universities and research entities around the world. For example, our collaboration with the University of Oxford on the PICASO project has revolutionised methods to design more cost-efficient and robust monopile foundations for our future wind farms.

- We continued to build on our culture of excellence in digital technologies by harnessing deep learning and generative AI to drive efficiencies and deliver greater value across both internal and external projects, from transforming the way we write winning bids, to leveraging AI models alongside drone technology to conduct inspections in the confined spaces of our offshore wind turbines.

- We developed the wind industry’s first uncrewed survey vessel, which uses onboard lidar to accurately predict offshore wind generation at prospective sites. It can operate in waters up to 200 metres deep and spend a year out at sea remotely operated from shore.

- We initiated Ørsted Propel, our in-house accelerator programme designed to support startups with the potential to revolutionise the energy sector. In our most recent round, we selected four startups out of 150 companies that pitched technologies from storing green power to decarbonising industry.

- We give our partners access to valuable resources including in-house expertise, renewable assets, data and capital, and we work alongside them at every stage of development: from finding the right concept, all the way to preparing a solution for commercial launch. By doing this, we widen our own innovative capabilities while actively building the renewable solutions of tomorrow – together.

I’m pleased that we’re releasing an overview of the broad range of innovation initiatives we’re pursuing at Ørsted. Every day, thousands of Ørsted scientists, engineers, and employees across many other functions throughout Europe, North America, and APAC work alongside our partners to scale and accelerate existing solutions while developing new technologies to help us push the boundaries of what we can achieve.

This report has three parts:

- Part 1: Offshore excellence: Innovation projects that lower costs and enhance performance across the full lifecycle of our offshore assets, spanning the design, construction, operation and decommissioning of an offshore wind farm.

- Part 2: Systems integration: Investments that enable energy systems to use more renewable energy and harness its value, across storage, grid balancing and technologies, decarbonisation of hard-to-abate sectors, green fuels produced from renewables, and carbon capture and management from biomass renewables.

- Part 3: Partnering to scale impact: Collaborations with innovators around the world to scale up technologies to advance the green transition, minimise the carbon footprint of renewables manufacturing and construction, and preserve sustainable ecosystems.

Innovation has been central to getting us where we are today, and it will be even more crucial in the coming years, as we continue working towards a world that runs entirely on green energy.

Rasmus Errboe

Deputy CEO & Chief Commercial Officer

Ready to read more? Go to Part 1: Offshore excellence.

300+

R&D and Open innovation projects in 2023

150+

Start-up engagements fuelling growth

52

Collaborations with universities

and research institutes

Looking to the future

In the last twelve months, we have made significant progress towards our vision of a world that runs entirely on green energy – with continued, rapid, and collaborative innovation central to many of our achievements.

As this report indicates, we will continue to collaborate with governments, industry partners, and research organisations to accelerate and scale the global green energy transition.

We encourage governments around the world to support this endeavour by boosting funding for the research, development, and demonstration of new technologies with the potential to transform the global energy system. There are signs of increasing support for a viable build-out of renewable energy from politicians and governments: in Europe, with the European Commission's proposed Net-Zero Industry Act; and in the US, with the Inflation Reduction Act. But this action must be further accelerated.

On a company level, we will continue working alongside industry, academia, the investment community and start-ups to explore and mature the technologies needed for a green transition that is fast, sustainable, and equitable.

Leadership is earned, and we don’t take our position for granted; as the global energy system transforms, Ørsted will remain at its forefront.

Contact us

As a global leader in renewable energy, we are harnessing innovation to optimise the way we work and deliver greater value across our core technologies. We feel confident in our ability to contribute towards the renewable energy system of the future. One that is secure, affordable, and runs entirely on green energy.

To drive impactful and lasting innovation, we will continue to partner with those leading organisations, start-ups, and academic institutions around the world that have the power to transform the energy industry.

So, whether you have an idea for an R&D project you want to partner on, or need support to build and scale your cutting-edge renewable energy technology – we want to collaborate.

Interested in working with us?

Reach out to us at [email protected] or head to

Innovation | Ørsted (orsted.com) to find out more.

Cookie Policy Website by KIRT x THOMSEN